lot traceability system

The major conceptual points of a robust lot traceability system include. Label the lot with the QR code labels or use existing barcode QR code labels if available.

Traceability Of Material When It Comes To Lot Traceability We Ve Got Your Back Digi

Traceability is a system in which fruits and vegetables can be traced from the field to the buyer by lot through unique codes.

. Together these systems ensure efficiency and accuracy in materials management. The benefits of Lot Traceability Tracks the part from receipt of materials into production and through to product delivery and inventory transaction records lotserial information Track which lot controlled items were used to produce specific finished products in manufacturing process. Track Materials When Received The first step begins when the raw materials are purchased and received.

Lot traceability is a group or lot of products that were made together in the same production run and produced using the same materials. BatchMasters lot traceability software can help food manufacturers exceed product traceability and recall code requirements stipulated in BRC SQF advanced food safety certification programs. The traceability of manufactured lots and batches serialized units includes the 5 Ms that is material human machine method and measurement.

A lot code could be a number number-letter combination or some other designation that is unique to the lot. The systems scans and validates lot numbers providing real time inventory usage and eliminating costly traceability paperwork. This feature of Blue Link ERP also allows you to perform lot costing tracking actual costs instead of FIFO or average.

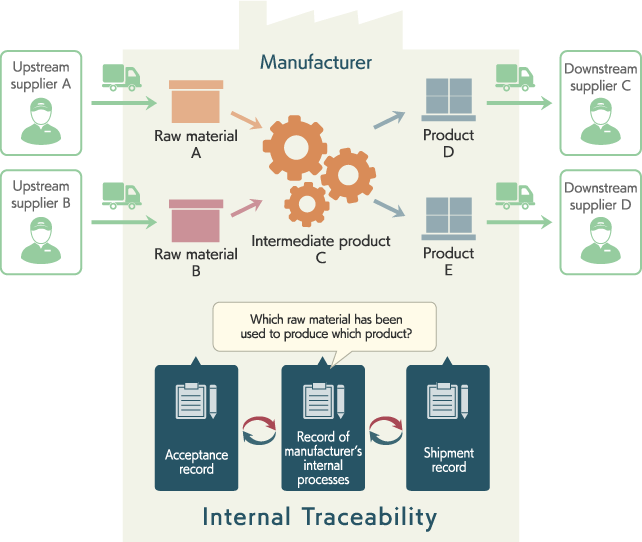

When adding traceability to the mix it allows manufacturers to track products throughout the supply chain. Traceability is the ability to trace all processes from procurement of raw materials to production consumption and disposal to clarify when and where the product was produced by whom Due to improving product quality and the rise in safety awareness in recent. Daily production reports show production and scrap per shift by traceable lot numbers.

Get control on a granular level with our lot level solution. Current Lot traceability system solutions are costly or imperfect and give rise to problems related to the organization and trust. Blank ware work-in-process and.

Its submitted by supervision in the best field. The term cradle-to-grave traceability refers to the ability to track lots from the beginning to end of the supply chain. In any case some important steps that must be taken.

The availability of a lot traceability system requires the development of traceability policies plans and procedures improving internal governance and driving compliance. Starting with the supplier who sends the raw materials moving through the manufacturing process and all the way to distribution and sale when the finished product reaches end customers. Hundreds of configuration options exist in the standard system enabling each workstation to be setup to handle many applications including batch campaign and combination weighing.

How The Lot Traceability Lot Number Tracking Works With QR Inventory Software Receiving New Materials Lot. Increasingly were seeing manufacturers invest in machine vision systems to keep better track of parts as they move through the assembly line. Scan the label and enter lot information into the system on a smartphone.

After tracking events in the supply market context seeing immutability as a fundamental rule of product handlers the company chose private blockchains and needed authorization. Lot traceability is the act of tracking and documenting a lot batch or group of goods that were made during the same manufacturing run using the same raw materials components and parts. Increase Customer Retention and Reduce Reputational Risk Lot Traceability with product recall functionality facilitates quick retrieval of sub-standard goods.

For ERP Integration see ERP Page. The use of lot traceability in Dynamics AX 2009 2012 and Dynamics 365 and CRM allow streamlining in order and inventory management and tracking effectively. A graphical lot traceability tool executes bi-directional searches to pinpoint on hold inventory vendor deliveries and customer shipments.

Key Features of Blue Link Lot Tracking Software. Each time inventory is transferred throughout the facility it is scanned and the location is updated in the inventory system ie. Here are a number of highest rated Scrap System pictures on internet.

Good lot traceability is bi-directional that is the lots path can be traced both upstream to its components and manufacturing process and downstream to customers and distributors. Industry-built to support your quality and safety systems SYSPROs Lot Traceability moduleoffers a full traceability system helping you improve governance and drive compliance to minimize the effects of a recall. Which materials and how much were used in the creation of a given batch of goods.

We identified it from honorable source. Key benefits of Lot Traceability Traceability of semi-finished or finished products from the supplier of raw materials through to the customer History of traceable-item transactions for accountability and customer service follow-up Manual or automatic lot numbering by single products or batch. We resign yourself to this nice of Scrap System graphic could possibly be the most trending topic gone we share it in google plus or facebook.

There are a variety of ways to achieve lot traceability including manually on paper by using electronic spreadsheets or through the use of an integrated system like IQMS. Move beyond supplier-product mapping to gain even greater control establish traceability at lot level from raw material to finished product to bring 100 confidence to your product and sustainability claims. This is done by assigning identification labels to each production run which can then be tracked.

Lot tracking is a core component in achieving FDA ISO CFIA compliance for many businesses. These correspond to time-stamped records of materials consumed operator electronic signatures equipment and tools utilized processes and exceptions and parametric and quality data collected. Basic Knowledge about Traceability an Indispensable System for Quality Management.

Each farm should have a traceability system in place that allows the grower to track. Lot traceability also known as Lot control or manufacturing traceability means a system which has the comprehensive functionality to track problems and provide full visibility of the.

What Is Traceability Traceability Solutions Keyence America

Basics Of Lot Traceability Recall Containment Youtube

Traceability Of Material When It Comes To Lot Traceability We Ve Got Your Back Digi

Lot Traceability Software For Process Manufacturing

What Is Traceability Traceability Solutions Keyence America

Traceability Lot Control And Quality Assurance Aim Computer Solutions

Traceability Of Material When It Comes To Lot Traceability We Ve Got Your Back Digi

What Is Traceability Traceability Solutions Keyence America

Product Information Traceability System

Traceability Lot Control And Quality Assurance Aim Computer Solutions

Structure Of A Food Traceability System Download Scientific Diagram

Traceability System Product Tsukasa Industry

Traceability In The Production Process Technical Article Macsa Id

Importance Of Lot Number Lot Number Tracking Capabilities

Lot Traceability Erp Software Lot Tracking Erp System Syspro

Lot Traceability And Recall Management System

What Is Traceability Traceability Solutions Keyence America

Operator Systems Track Trace Production Across The Entire Supply Chain Production Genealogy

Comments

Post a Comment